The horizontal forging machine adopts German technology and also improved after many years application,

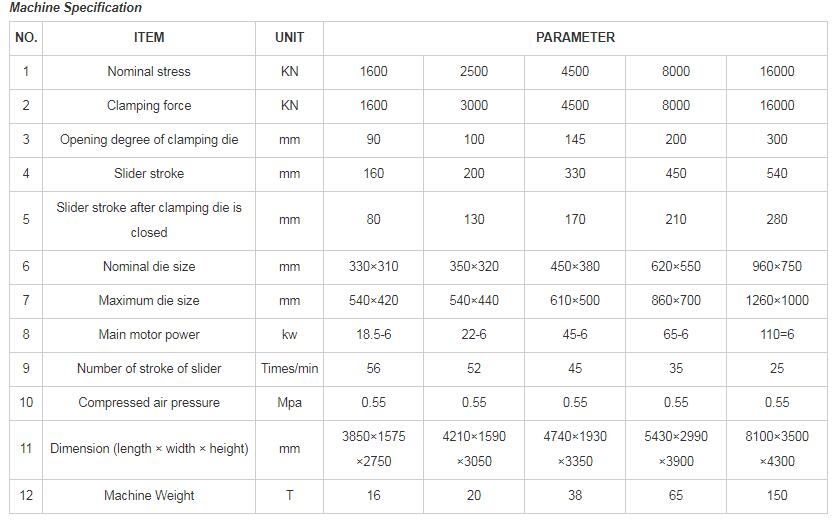

which is the advanced technology with for long workpiece forging.

Overview

The horizontal forging machine adopts German technology and also improved after many years application,

which is the advanced technology with for long workpiece forging.

The machine has a high degree of automation, with man-machine interface, automatic lubrication,

automatic alarm and other functions, is the ideal model for long forging.

The horizontal forging machine has a wide range of applications,

mainly producing socket wrench, railway forks, bolts, auto parts and other fields.

Application

Hot Tags: horizontal forging, suppliers, manufacturers, customized, Laser Edge Hardening Machine, Tap Sharpener,

Valve Testing Machine, forging rolling mill, Laser Cutting Edge Hardening Machine, surface hardening

Machine Feature

The horizontal forging machine mainly includes clutch brake, frame, slider, clamping mechanism, retaining mechanism,

crankshaft, drive shaft, motor device, pneumatic device, lubrication system, protection device and electrical system.

1. Clutch, brake, flywheel

Clutch and brake using Italian integral structure, the advantages of simple structure, large transfer torque, easy to replace

the friction block, improve the service life of the friction block, ensure that the brake work for a long time, reliable work.

2. Machine frame

The frame is the main structure for the equipment to bear the longitudinal upsetting force. It is mainly composed of

the upper beam and the lower fuselage, and other mechanisms and components are installed on the fuselage.

The upper and lower fuselage adopts integral welded thick-wall structure, and the material adopts Q235.

3. Slider

The slider is an elephant trunk type pressure-bearing box casting, the material is Q235, it is driven by the crank of the

crankshaft through the connecting rod, making the reciprocating movement for upsetting the work of the slider before

and after the guide rail guidance, anti-partial load ability is strong, upsetting forming workpiece precision is high.

4. Clamp mechanism

Clamping mechanism is composed of solid rod connecting rod mechanism, it is driven by the same crankshaft driving slider,

by cam eccentric clamping, driven on the fuselage clamping slider up and down, in the vertical direction of the bar clamping

bar material, so that the slider upsetting forging, metal forming in the mold cavity.

The lower hinge of the clamping connecting rod is provided with an eccentric adjusting device.

In the clamping mechanism, a set of overload protection device is installed to prevent overload during clamping.

5. Crankshaft

The crankshaft bears upsetting force directly and is one of the most important parts in the horizontal forging machine.

The blank is forged as a whole and processed by the crankshaft machine tool.

The material adopts 40Cr forgings and quenched and tempered treatment to ensure strength, rigidity and enough toughness.

6. Shaft

The drive shaft is composed of flywheel and pinion device, which transfer the torque to the crankshaft, respectively made of 40Cr material.

The drive shaft and flywheel are connected by expanding sleeve for easy maintenance.

7. Motor device

The motor device is used to transfer the torque of the motor to the drive shaft through the triangle belt.

The motor adopts YH2 high slip series, and the horizontal forging machine adopts 22KW-6.

8. Pneumatic devices

8.1 Pneumatic device is the control device of this machine, which is used to control the interlocking coordination of clutch and brake,

and to control the starting or stopping of the machine.

8.2 The pneumatic device is composed of water filter, pressure regulating valve, pressure gauge, oil mist device,

interlock air distribution valve, flywheel brake, air storage tank, etc.

8.3 The water separator filters the water in the compressed air from the main pipe through the pressure

valve, air storage tank, oil mist device, clutch distribution valve to the clutch.

8.4 The pneumatic device adopts the combined control mode of electricity and gas (with pressure relay and interlocking function with electricity).

The solenoid valve installed on the brake and clutch distribution valve is controlled by foot switch when working.

When the pedal switch is pressed, the machine starts. In this process, the clutch is attached later than the brake is released.

The length of the delay is adjusted by the throttle valve installed on the clutch air distribution valve.

After a working cycle, the cams installed at the crankshaft end hit the travel switch, making the machine stop.

In the process of braking, the brake should stop later than the clutch disengagement, the length of time after

the delay depends on the throttle valve installed on the air distribution valve of the brake to adjust.

The lubricator turns the oil into a mist and lubricates the clutch and brake cylinders.

8.5 Interlock air distribution valve is controlled by foot switch.

8.6 Air pressure of pneumatic system is 5.5-- 6kgf/cm², working pressure of clutch and brake is 5.5 KGF /cm².

9. Lubrication system

Adopts progressive distributor lubrication, can realize the quantitative oil supply.

Increase the oil groove in the oil supply part, and change the key oil supply part to double oil circuit.

Oil gun lubrication, oil lubrication and electric dry oil pump automatic intermittent oil supply combination.

9.1 There are a total of 28 lubrication points of the machine, 4 of which are filled with manual oil gun,

and the type of automatic dry oil pump is BS-B electric dry oil pump.

Lubricating oil with no. 0 or no. 2 lithium (or sodium) based grease.

The progressive lubrication system consists of an electric pump, a progressive distributor and a monitoring system

10. Cooling device

The horizontal forging machine adopts air cooling, simple structure, convenient and durable.

11. Protective devices

In order to prevent personal accidents and equipment damage, the moving parts of the machine adopt protective cover as a protective device.

For big order or customized order, Pls feel free to contact service@kiggg.com

Kiggg.com is the professional workshop machinery supplier for more than 10 years. We supply various workshop machineries,

like the CNC VMC, CNC Lathe, CNC Gantry Machining Center, metal sheet working machine, pipe working machine etc.

In the meanwhile, we have been also supplied the turn-key project for some fields, like auto parts, hand tools etc.