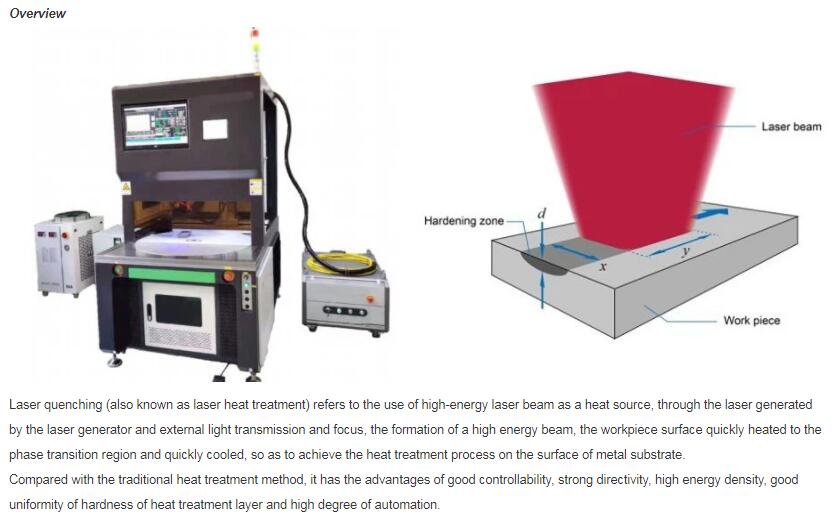

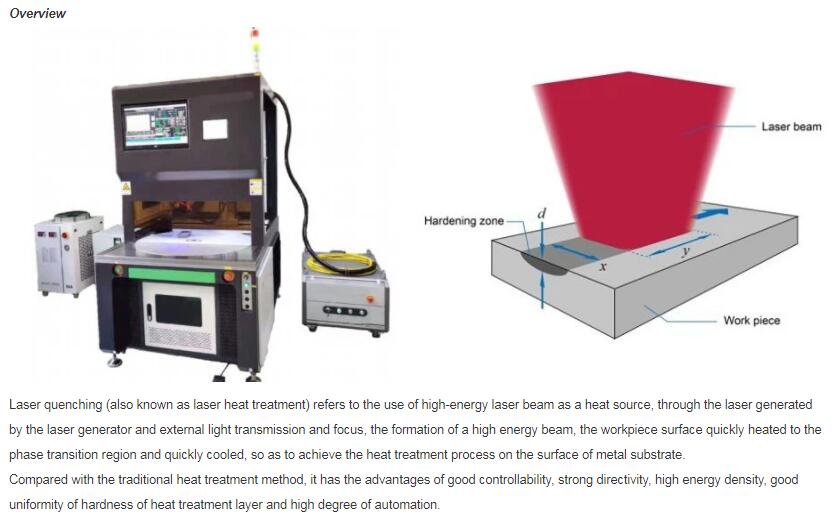

Laser quenching (also known as laser heat treatment) refers to the use of high-energy laser beam as a heat source,

through the laser generated by the laser generator and external light transmission and focus, the formation

of a high energy beam, the workpiece surface quickly heated to the phase transition region and quickly cooled,

so as to achieve the heat treatment process on the surface of metal substrate.

Hot Tags: laser cutting edge hardening machine, suppliers, manufacturers, customized, automatic pliers polishingmachine,

Hydraulic Cold Extrusion Press, Laser Cutting Edge Hardening Machine, Tube polishing machine, cast iron pipe cutter, Laser Welding

Machine Feature

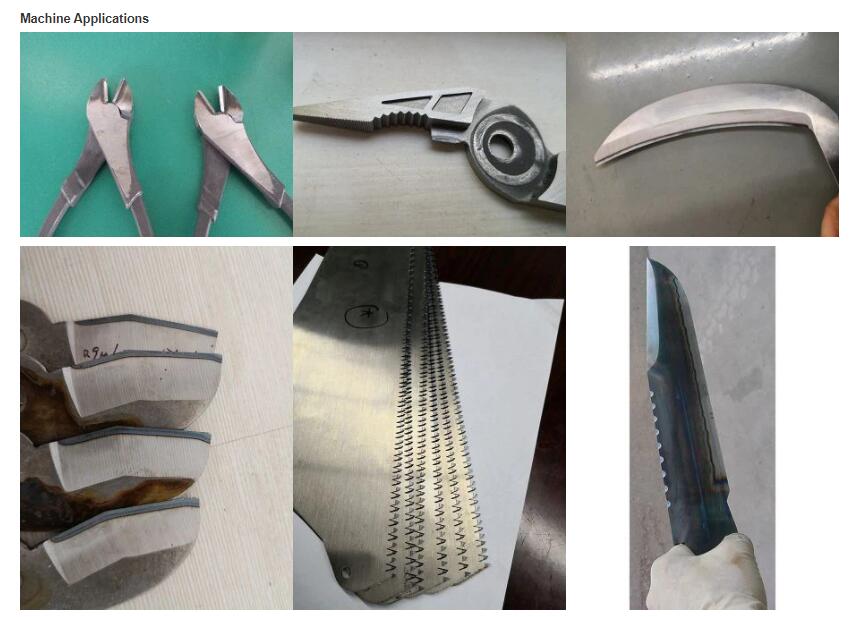

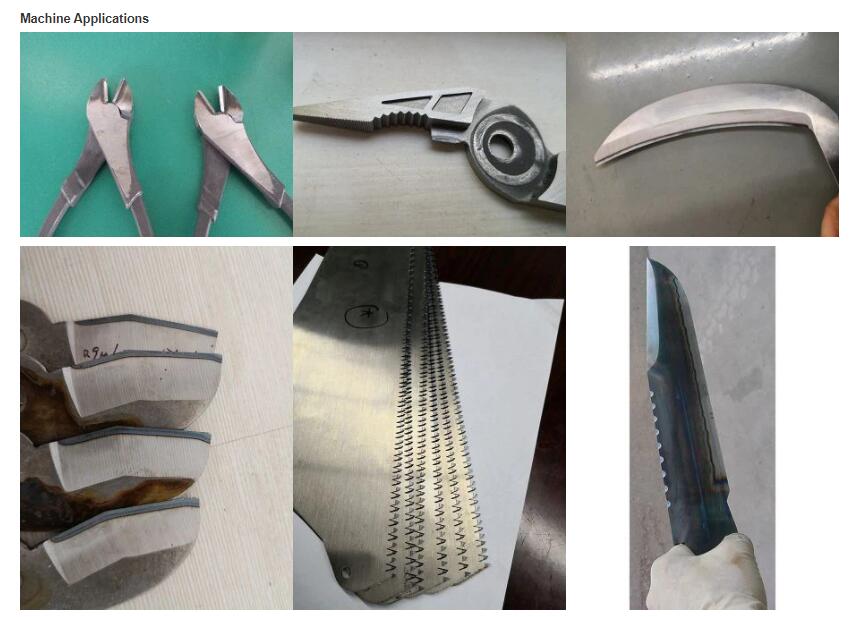

1. Better evenness of hardening

As long as the laser can be irradiated, such as the tooth tip, cutting edge, etc., the hardness is consistent

2. No need quenching water

Due to fast heating speed of the laser, the hardening can be done immediately and no need cooling medium required.

3. No deformation no oxidation and decarburization

Thanks to very precise laser beam, it will be only effect on hardening area, so there is no deformation.

Small heat affected zone, no deformation, almost no oxidation and decarburization.

3. Better hardening performance

After quenching, the hardness is uniform and the structure is fine, which is higher than the conventional quenching

(2-5HRC), the hardening layer is 0.2-1.5mm deep, and the wear resistance and life can be increased by 3-5 times.

4. No black hardening part

There is no black part in quenching, and the shear performance is greatly improved.

5. Saving power consumption

Power consumption of 7KW/h, comparing with conventional induction heating, it is very less.

6. No need skilled worker

This is an automatic CNC machine with rotary table, so operator just need to put the workpiece.

7. Better working environment

The machine is equipped with good-looking enclosure and the quenching water is not required, so it can be located clean workshop.

For big order or customized order, Pls feel free to contact service@kiggg.com

Kiggg.com is the professional workshop machinery supplier for more than 10 years. We supply various workshop machineries,

like the CNC VMC, CNC Lathe, CNC Gantry Machining Center, metal sheet working machine, pipe working machine etc.

In the meanwhile, we have been also supplied the turn-key project for some fields, like auto parts, hand tools etc.