1. Unique structure design. Worktable doesn't do linear motion.

2. Twin pallet improve production efficiency.

3. Belt driven spindle 12000rpm.

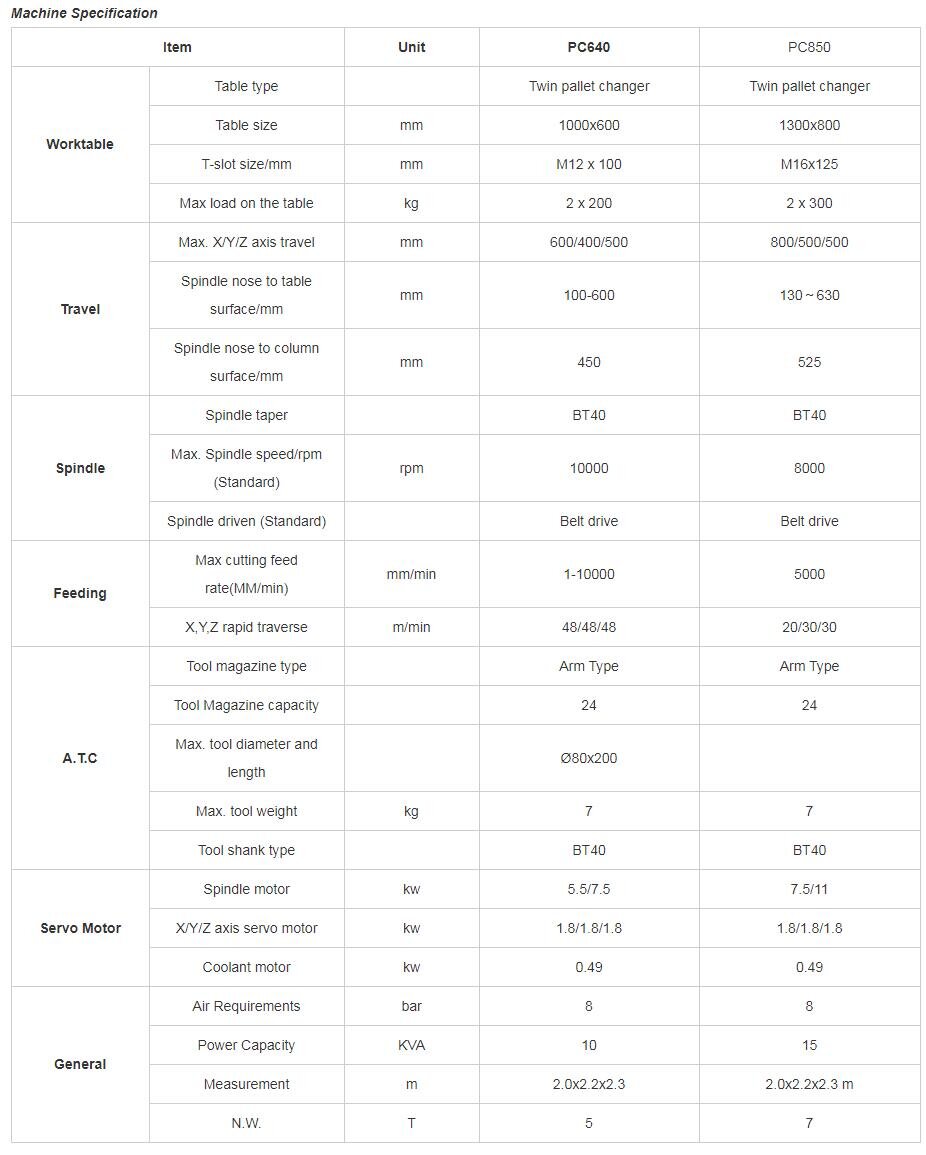

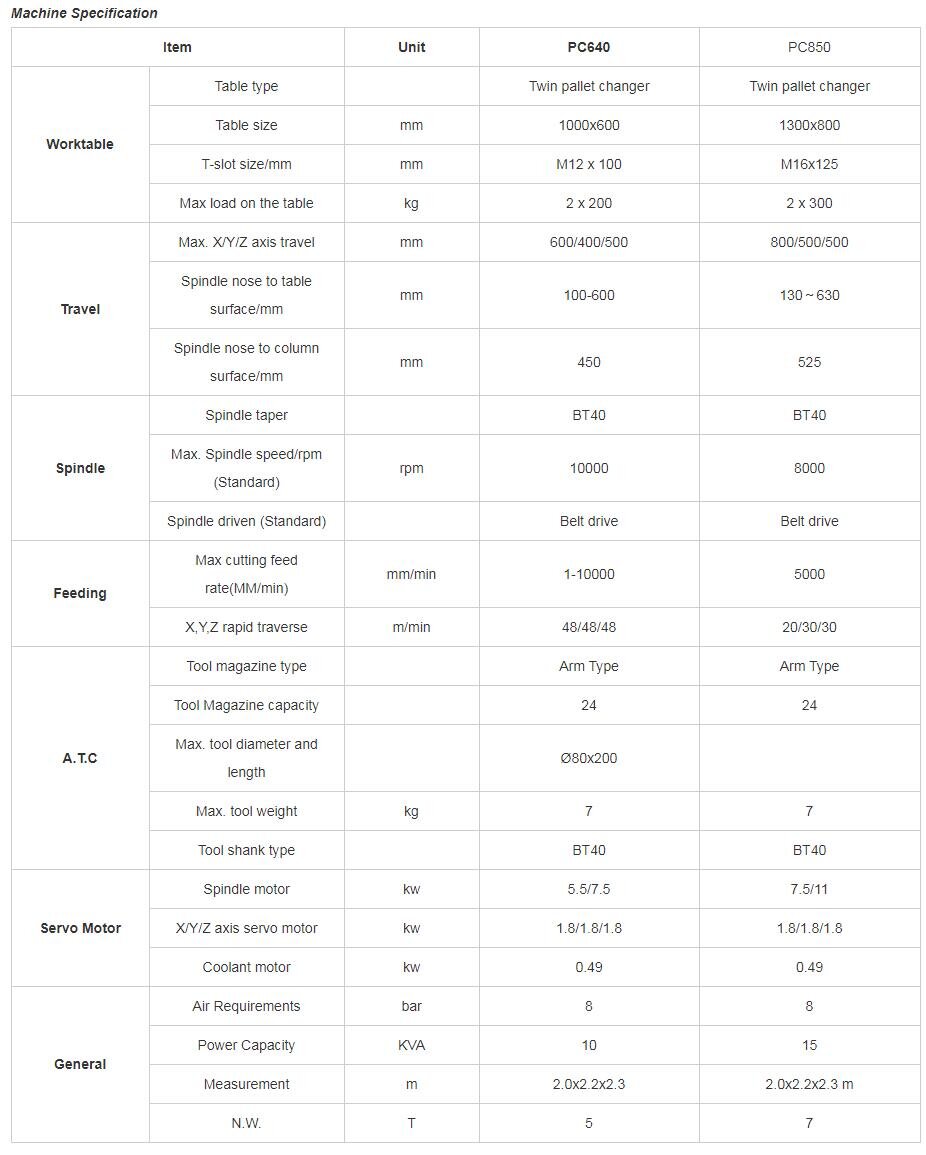

Overview

Twin pallet vertical machining center

1. Unique structure design. Worktable doesn't do linear motion.

2. Twin pallet improve production efficiency.

3. Belt driven spindle 12000rpm.

4. Precision Linear Guiderail made in Taiwan on three axes. X/Y/Z axis rapids 48m/min.

5. Improved tool magazine with random shortest tool path.

6. Ballscrews on 3 axes are locked to base seat by double nuts on both sides. Pretensioned

ballscrews can eliminate the backlash and pre-compensate the error ruslted from heat growth.

Servo motors are directly coupled with ballscrews.

Hot Tags: pallet changer vertical machining center, suppliers, manufacturers, customized,

Rolling Machine, induction brazing equipment, Pipe Bending, gantry machining,

CNC Hand Tools Polishing Machine, plier edge hardening machine

Machine Feature

1. Machine body

Adopt advanced resin sand casting and box structure design and manufacture, after aging treatment to

eliminate internal stress, tough material, plus box structure design, high rigid body structure, so that the

machining center has enough rigidity and strength to show the machine cutting ability and high precision characteristics.

2. Drive axes

X/Y/Z axis adopts linear line rail sliding rail design.

The column, saddle, head and base are made of high grade resin sand casting and box structure design

and manufacture. Through computer analysis, the rib configuration is strengthened to improve rigidity and stability.

3. Screw

The three-axis adopts precision ball screw with high precision double nut preloading, and with the lock

and pull design of support seats at both ends, it can eliminate the transmission backgap and compensate

the errors caused by temperature rise in advance, so as to ensure the positioning accuracy.

4. Spindle motor

Adopt high speed motor, so that the machining center in high speed, low speed and light,

heavy cutting has very good performance (power up to 3.75/5.5KW).

5. Spindle head

Using high precision, high rigidity spindle head, it can bear the radial and axial load of heavy

cutting and longtime heavy cutting, and can maintain the high precision of machining.

6. ATC (optional)

Adopt umbrella/disc type, provide fast, stable and reliable tool exchange action, controlled by

PLC software, fast and quick tool change action, reduce non-cutting time.

7. Control cabinet

The control cabinet is equipped with a heat exchanger to ensure the stability of the system.

The outer wiring part has a protective snake tube, which can withstand heat and oil and water.

8. Lubrication system

The automatic lubrication system is used to centralize oil supply, and the advanced depressure-intermittent

oil supply system is used to provide timely and appropriate oil supply to each lubrication point in a regular,

quantitative, constant pressure and individual manner, so as to ensure that each lubrication position can get

the lubricating oil on time, so that the processing center can operate for a long time without worries.

9. Machine Enclosure

In today's environmental protection and the operator safety considerations under the strong requirements,

the best speed precision machine on the best speed CNC machining center plate gold design focuses on

the appearance of the United States, environmental protection and ergonomic.

The fully sealed plate gold design prevents the cutting fluid and cutting fluid from splashing outside

the drilling and milling machine, so that the surrounding of the drilling and milling machine can keep clean.

For big order or customized order, Pls feel free to contact service@kiggg.com

Kiggg.com is the professional workshop machinery supplier for more than 10 years. We supply various workshop machineries,

like the CNC VMC, CNC Lathe, CNC Gantry Machining Center, metal sheet working machine, pipe working machine etc.

In the meanwhile, we have been also supplied the turn-key project for some fields, like auto parts, hand tools etc.