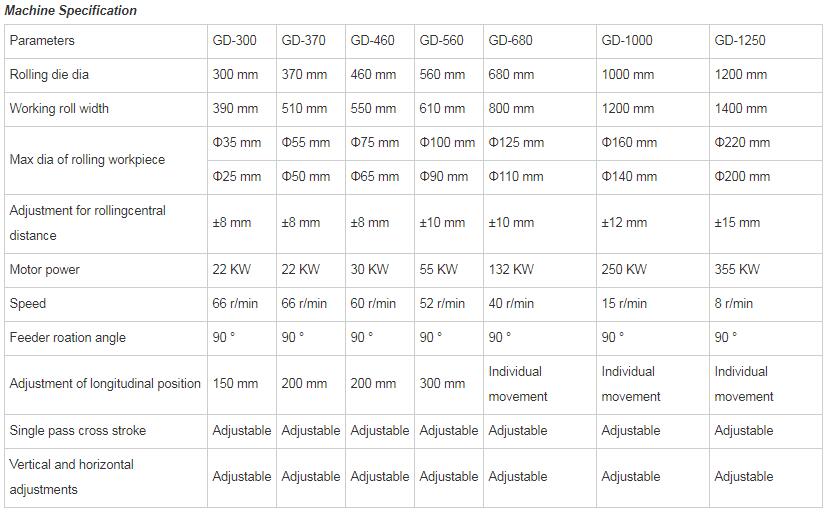

Radial Rolling Mill

The listed price is not real price, For correct product's price or customized product, Pls feel free to contact service@kiggg.com or Pls contact WhatsApp +86 13062213712 Adam Wang

Kiggg.com is the professional workshop machinery supplier for more than 10 years. We supply various workshop machineries, like the CNC VMC, CNC Lathe, CNC Gantry Machining Center, metal sheet working machine, pipe working machine etc. In the meanwhile, we have been also supplied the turn-key project for some fields, like auto parts, hand tools etc.